For simplification, enhancement of a gemstone using any colourless material in the filling of fractures, cavities or voids and for the compaction of porous materials is considered under a single heading.

- Nature of gemstone:

- Any stone which contains surface reaching fractures.

- Porous stones.

- Materials used: Oil (cedar wood oil, linseed oil etc.), Canada balsam, wax, plastic, polymers, resins, glass etc.

- Possible effects:

- Usage of fracture filler having a similar refractive index as that of the stone reduces the visibility of the fractures and thereby improves the clarity of the stone.

- In the case of porous stones, the internal pores and those on the surface are sealed, thus improving the overall durability of the stone as well as its surface lustre.

- Porous stones which exhibit a phenomenon can be stabilized by bonding as a result of which the phenomenal effect is also enhanced.

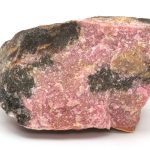

- Stones enhanced: Almost any stone can be enhanced in this manner. For convenience, only a few of the most routine stones are considered with respect to the materials used.

- Colourless oil: As per CIBJO regulations, the colourless oiling of emerald, aquamarine, ruby, sapphire etc. is an accepted trade practice and does not require to be disclosed. Most of the oils used are those which are not affected by temperature changes i.e. they do not freeze and solidify in cold weather.

- Colourless Resin: Organic resins, such as epoxy resins are being used more often as they are more stable as fracture fillers. Emerald, Aquamarine, Iolite, Amethyst, Peridot and Tourmaline are some of the stones whose fractures are filled with resin. The brand name of opticon has inadvertently got linked up with resin filling, and it is not uncommon to hear the term opticon treated stone among traders.

- Mixtures of colourless oils and resins.

- Polymers/wax/plastic: These are basically used as bonding materials for porous stones such as turquoise, coral, opal, jade etc.

- Glass: Lead glass is currently used as fracture filler for diamond and ruby. The lead glass fracture filling in diamond was originally promoted by Mr.Yehuda and the term Yehuda Diamond is often met with among traders. Glass filling in ruby is done to fill fractures as well as surface pits, twin planes and cavities.

A large variety of fillers are being made available in the market on a daily basis and identification of each and every one is outside the scope of this book. Needless to say, a student must be aware of the developments in this field. E.g. fillers which harden within a fracture when exposed to ultra violet radiations.

- Identification: The criteria used to identify impregnations is quite distinct for fracture filled stones and porous stones.

- Fracture filled:

- First locate the surface break of the fracture. It appears as a thin line on the surface and can be better observed by reflecting light off the surface of the stone.

- Locate the direction in which the fracture is oriented within the stone.

- Reflect light off the fracture surface and observe any or all of the following:

- Trapped gas bubbles in the fracture due to incorrect filling.

- A single colour flash is seen which changes when the stone is rotated 90°. Common colour flashes seen are yellow / orange to blue, or violet to pink.

- Lumpy and unequal patches within the fracture indicate incorrect filling.

- U.V. Fluorescence: Some filler may fluoresce distinctly different from the body colour of the stone.

- Hot Point: This may help to identify a filling in a fracture, but is a destructive test and should be used as a last resort.

- Surface Lustre: In some cases, a distinct lustre difference is observed between the stone and the filled fracture.

- Porous stones:

- Magnification: Under low magnification the impregnated porous stones may show a speckled or slightly sugary appearance.

- U.V. Fluorescence: Some filler may show distinctly different fluorescence from the body colour of the stone.

- Hot Point: This may help to identify different impregnating material – polymer, wax and plastic will give a peculiar and distinct odour and may melt where the hot point is applied.

- Surface luster: Porous stones impregnated with wax generally have a waxy lustre.

- Other techniques: To conclusively detect the exact nature of impregnated materials (whether oil, resin or wax) it is necessary to resort to Infra-Red and / or, Raman Spectroscopy, X-ray Diffraction or SEM (Scanning Electron Microscope).

- Fracture filled:

The need for identification of the exact nature of the filler material is of prime importance these days and as a result sophisticated equipment are a compulsory feature in laboratories.

Leave a Reply

You must be logged in to post a comment.